PPC116 | Health and Safety

It can be frustrating, being smothered in ‘bubble wrap’ as an adult but, in an industry with diverse, potentially dangerous environments, ensuring safety is paramount. The red tape is there to protect us so that we can go home safe and well at the end of every day.

Personal protective equipment (PPE) and respiratory protective equipment (RPE) are crucial measures we should take to protect ourselves.

Both play vital roles in safeguarding pest professionals from various hazards. And if you manage a staff team, encouraging the correct use of these will foster a culture of safety and compliance and keep you on the right side of the law!

But, before we discuss PPE and RPE further, you need to understand one key principle: these are the options of last resort.

An online CPD quiz based on this feature is now available on the BPCA website. BPCA Registered members and affiliates can take a CPD quiz at any time bpca.org.uk/find-cpd

or sign up at bpca.org.uk/affiliate |

What is PPE?

Personal protective equipment (PPE) encompasses a wide range of gear designed to protect pest managers from physical, chemical, biological and ergonomic hazards. Types of PPE vary depending on the industry and the specific risks involved.

Head – helmets, bump caps and hard hats protect against head injuries from falling objects or accidental bumps. These are important for spaces such as attics (bump risk) and construction sites. If you are installing bird netting on a roof, head protection is a must.

Eyes – safety glasses, goggles and face shields prevent injuries from flying particles, chemical splashes and intense light. We may also use these when, for example, cleaning and clearing bird fouling.

Hands – gloves protect against chemicals, cuts, abrasions and thermal hazards. Different levels of protection will be needed depending on the task at hand. Bait box checking may just require a good pair of disposable gloves, but spraying and fogging will require a tougher material to prevent chemical absorption.

Feet – safety boots and shoes prevent injuries from falling objects, punctures and slips. If you’re onsite doing a survey or working for a client, they may require you to wear safety boots as per their own risk mitigation strategies.

Body – overalls, aprons and protective suits shield against chemical splashes, hot surfaces and biological agents. Bee and wasp suits with veils should form a big part of a pest manager’s equipment!

“Spraying liquid insecticides became a much smaller part of our jobs, negating the need to wear RPE at all! ”

What is RPE?

Respiratory protective equipment (RPE) is a subset of PPE specifically designed to protect the respiratory system from inhaling hazardous substances. RPE is crucial in environments where workers are exposed to dust, fumes, vapours and gases that can cause respiratory illnesses or exacerbate existing conditions.

As pest professionals often use dust formulations or even fumigants, RPE is an incredibly important piece of safety equipment.

Disposable respirators, often known as dust masks, are used for protection against particulates.

Half-face respirators provide a higher level of protection against dust, fumes and mists.

Full-face respirators offer protection for the entire face, used in environments with toxic gases and vapours.

Powered air-purifying respirators (PAPRs) use a battery-powered blower to filter contaminated air.

Self-contained breathing apparatus (SCBA) is used in highly hazardous environments, providing air from a tank.

Selection and use

Selecting the appropriate PPE and RPE involves a thorough risk assessment to identify potential hazards. Employers (or you, if you’re self-employed) must ensure that the equipment fits well, is comfortable, and is suitable for the specific tasks and environmental conditions.

Training – workers must be trained on the correct use, maintenance and limitations of PPE and RPE. This includes proper donning and doffing techniques, and recognition of when equipment needs replacement.

Maintenance – regular inspection and maintenance of PPE and RPE are critical. Damaged or worn-out equipment can fail to provide adequate protection.

Fit testing is essential for RPE to ensure a proper seal and effective protection. This is particularly important for respirators which must form a tight seal around the nose and mouth. Each individual’s face shape, including facial hair, needs to be considered.

If appropriate RPE cannot be obtained, workers must not be put to work where it is required to protect their health.

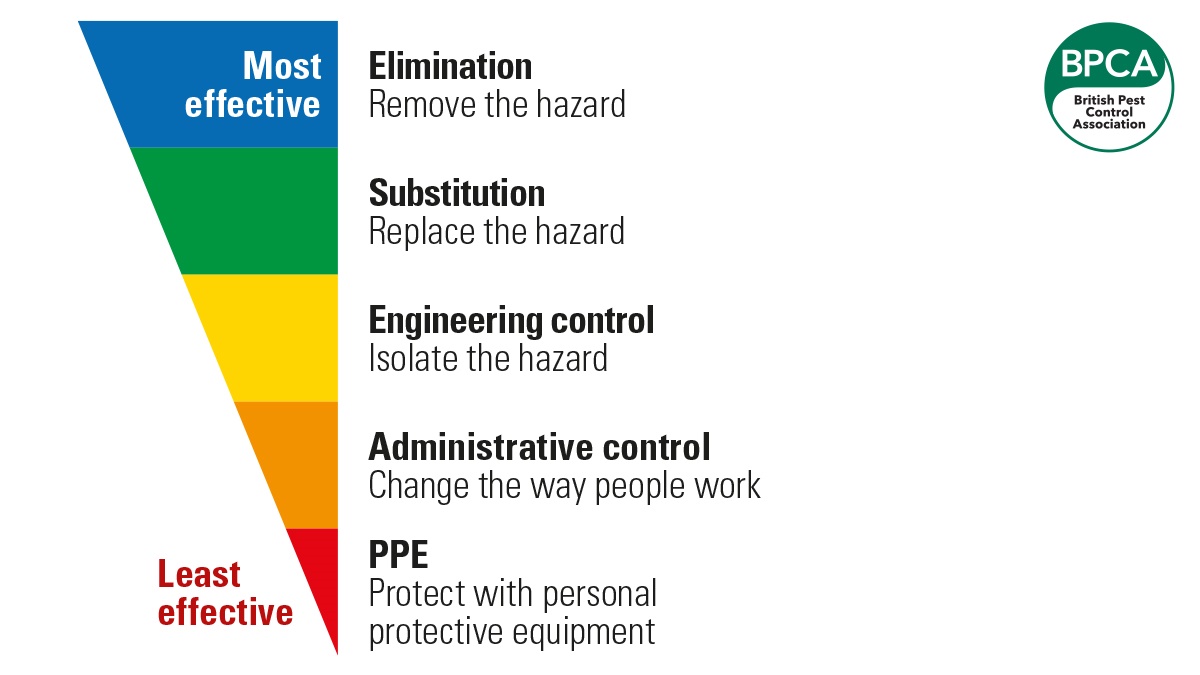

COSHH risk hierarchy

As a health and safety buff, I love a good risk hierarchy. The Control of Substances Hazardous to Health (COSHH) risk hierarchy is the guide for good practice for reducing risk when carrying out pest control.

Examples of the risk hierarchy in action:

- Substitution control: swap high ladders for surveys for a drone survey

- Engineering control: ant and cockroach gel baits; lance applicator for aluminium phosphide for mole tunnels; ready-to-use, pre-mixed insecticide

- Administrative control: implementing non-chemical pest management, eg recommend waste removal to reduce flies and thereby remove the need for chemical treatment.

Over the years, we have seen some significant advances in product formulation in pest management. We now have more advanced options and safer application techniques.

Think of ant and cockroach gel baits, for example. The introduction of this delivery method and formulation made things so much safer for the pest technician and, in turn, the customer. Spraying liquid insecticides became a much smaller part of our jobs, negating the need to wear RPE at all!

The change from spraying to using gel baits would come under the substitution and engineering control of the hazard. The insecticide used, and the delivery method are now substituted for a safer delivery method, and the application gun and gel tube isolate the user from the insecticide almost completely – perfect!

Challenges and considerations

Despite the clear benefits, there are challenges associated with the use of PPE and RPE.

Comfort and usability – uncomfortable or cumbersome equipment can discourage use. Balancing protection with comfort is essential to ensure compliance.

Cost – high-quality PPE and RPE can be expensive, but investing in safety can reduce the overall costs associated with workplace injuries and illnesses.

Cultural and behavioural factors – encouraging consistent use of PPE and RPE requires fostering a safety culture within the organisation. This involves leadership commitment and continuous education, and leading by example!

Importance of PPE and RPE

The primary importance of PPE and RPE lies in their ability to prevent workplace injuries and illnesses. By providing a barrier against hazards, they ensure that workers can perform their tasks safely and efficiently.

PPE and RPE are integral to maintaining a safe and healthy workplace. By understanding their importance, selecting the right equipment, and ensuring proper use and maintenance, you can be protected effectively and reduce workplace risk.

Regulatory compliance

Using PPE and RPE is not just a best practice but often a legal requirement. Regulatory bodies like the Health and Safety Executive (HSE) mandate specific PPE standards to ensure workplace safety.

This is facilitated through legislation such as the Health and Safety at Work Act 1974 (HASWA). Employers are legally required to provide employees with the appropriate PPE and RPE, ensure maintenance, and not make employees pay for said equipment. Employees have a responsibility to follow their employer’s instructions to use PPE and RPE.

Health – proper use of PPE and RPE can prevent acute injuries and long-term health issues, such

as respiratory diseases, skin conditions and hearing loss.

Productivity and morale – a safe working environment boosts employee morale and productivity. Workers who feel protected are more likely to be engaged and committed to their roles.

Moral responsibility – nobody wants to experience injury or illness, or allow this to happen; the provision of PPE and RPE ensures adherence to proper ethical and moral responsibilities.

|