Technical | PPC92 September 2018

With an extensive choice of bird control and proofing products available, there are many factors to take into consideration when selecting the most suitable netting products for the job. PestFix Director, Dan England, shares his expertise with the readers of PPC magazine.

n the majority of cases the best way to protect a man-made structure from infesting birds in a high pressure situation is to install bird control netting. There are different types of bird proofing which are suited to varying levels of bird pressure. For example, bird repellent gels and bioacoustics work well in low pressure situations. They are not recommended for use in high pressure infestations where the birds are more compelled to remain.

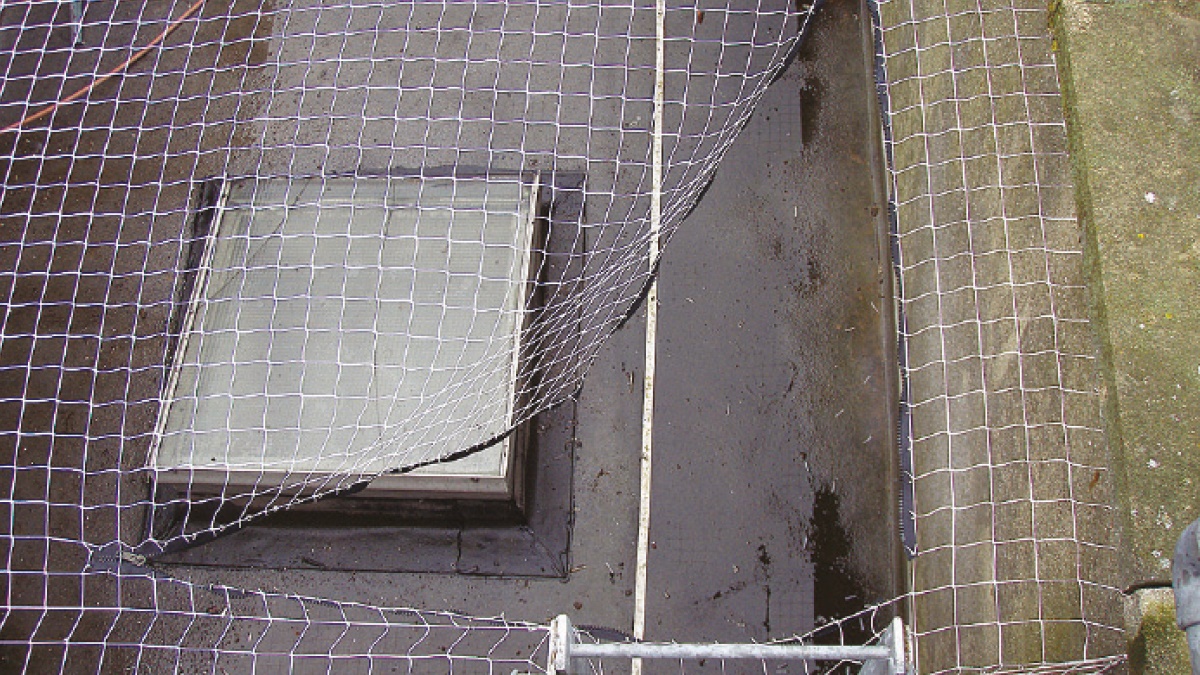

Bird control netting is the only bird proofing solution that places a physical barrier between the pest bird and its intended destination. Bird netting is especially suited to protecting large surface areas, for example, industrial roofs.

How is bird netting manufactured?

Bird netting is manufactured from extruded 630 denier (0.3mm thick) high density polyethylene (HDPE) monofilament.

HDPE is supplied in beads or granules which are melted and mixed with additives that may include colour pigments, ultraviolet filters and flame-retardant ingredients before being extruded into a 0.3mm monofilament.

To make the finished twine, the monofilament is twisted into a bundle of three and again into a bundle 3x3 to make the finished twine of nine monofilaments, approximately 1mm in diameter. This twine is referred to as 12/9 construction. The finished twine has a breaking strength of 14kg, and when made into a net, the breaking strength can be much greater.

The loom joins the twine together into a knotted mesh, which is then subjected to a five tonne load to pull the knotted junctions tight. Then the knots are subjected to a high heat source which sets the knotted junctions and prevents slippage. All bird netting comes off the loom in a diamond configuration.

The nets are hand-finished using highly skilled labour. They are squared off, then cut down to size or joined together to make larger sizes.

Smaller mesh size nets will relax back into a diamond shape and will need to be stretched out to shape before installation.

Joining nets neatly and accurately is one of the most highly skilled jobs in the manufacturing process as it is all done by hand.

Bird netting types

To reduce cost and weight, we use the largest possible mesh size that is applicable to the species of bird concerned. Larger mesh nets are less susceptible to wind loading and less visible. However, we have to select the appropriate mesh size for the species of bird concerned. Size options available include 75mm seagull, 50mm pigeon, 28mm starling and 19mm sparrow. When proofing against multiple species select the smallest species mesh size.

Other considerations when choosing netting

Net colours

“You can have any colour, as long as it is black?” All too often we see black netting being mis-specified and installed. Other colours are available which may be more suitable for applications such as building façade nets, skyline nets and nets in front of windows or courtyards and lightwells.

Reaction to heat and fire

HDPE has a melting point of 130°C. When exposed to naked flame it will readily ignite and propagate fire rapidly across the netted area by dripping molten flaming plastic everywhere. It is best to use flame retardant netting for indoor use or where there are people or combustible materials present beneath it.

Installing bird control netting: the netting label

Pay attention to the netting label and corner tell-tales:

- The labels advise us of the mesh size, twine construction, colour and fire rating (if any)

- The label also denotes the longest edge on rectangular nets which is crucial when working with nets of a similar length and breadth dimension ie a 25m x 26m net

- The label is attached to the net three to four mesh squares in from the corner on the longest edge

- It also assists installers when working in a confined space or at night

- DO NOT REMOVE until the job is complete

- Always start your installation along the longest edge.

- Tell-tales are contrasting coloured twine that denotes the corners of the net:

- This eases corner identification

- Always start at a corner.

Netting and the law

Two key legal implications to consider when installing netting:

Will it trap the birds?

This can be avoided by careful design and regular maintenance to avoid falling fowl (ahem) of the Animal Welfare Act 2006.

This is ultimately the building owner’s legal duty, but you need to protect your customers.

Planning permission?

It’s rare that this is needed, but if in doubt have your customer check with the local authority, especially if the building is listed, or if the netting will alter the building’s appearance. It is the responsibility of the owner or occupier, but you should give proper advice.

Key components of a netting system

The netting itself is just a small part of the overall system that makes up a netting installation. Like all systems, a netting installation will only be as effective as its weakest component.

Therefore, careful planning and installation are essential to success. Your supplier will be able to provide you with detailed technical specifications for their netting systems which will give you essential information on the type and number of components needed. Each netting installation will vary from the next and will need a unique blend of components. Great care should be taken during the surveying and planning phase of any job to ensure success. If in doubt, ask your supplier for technical support.

Corner and intermediate fixings

These are the foundation of any netting system and are vital to its success. There is a myriad of fixings available depending on what type of substrate you are fixing to and what level of corrosion resistance is required. Below is just a small example of the range available.

Netting mounts/brackets

Netting mounts can be integrated into the netting framework to lift the netting system clear of any obstacles. They are also used to create sufficient clearance between the net and the surface being protected to prevent the pest birds from pushing down the net and overwhelming it.

Access zips can be stapled into the netting after its installation to allow for maintenance access. This can help prevent damage to the nets by other tradespeople cutting their own holes.

Wire rope and tensioning products

These are used in conjunction with corner and intermediate fixings to create a tensioned wire framework, over which the netting is fastened.

Specialist netting tools

You will need a range of tools for installing bird netting:

- Ratchet crimp tools for terminating wire rope ferrules

- Side cutters for creating clean cuts through perimeter wire rope without fraying (caused by pliers or conventional snips that crush)

- Professional sprung netting shears for one-handed cutting

- Hog ring pliers that are compatible with the hog ring staples.

Remember!

Good pest management should focus on prevention and not cure, by keeping areas clean and free from food and rubbish - remove the source, remove the problem. Bird control netting is no substitute for good housekeeping.

Netting installations require regular service visits and maintenance.

If you are not sure what is available for a particular project call your supplier for technical support.

Dan England

Dan England

Pestfix

September 2018 | PPC92